After polishing the piston body, I continued with the cocking lever.

Any sliding or pivoting metal-to-metal surfaces get hit on the buffer.

Don't forget the ears on the rocker.

The cocking lever pivot pin got the business, too.

Springtime notes: The stock spring was 8.875" long. OD was 0.765" Wire diameter 0.100" ID is 0.565". The spring was a very loose fit both on the spring guide as well as inside the piston body. The spring guide is 0.479" diameter and 2.00" long--not including the flange at the base.

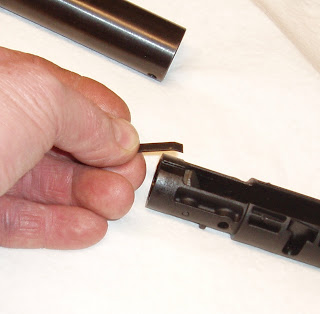

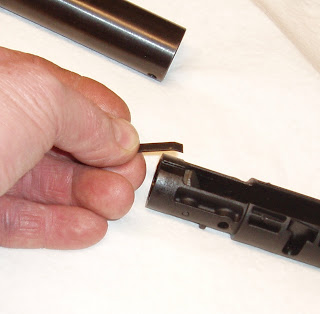

This is one way to sleeve the inside of the piston to tighten the spring fit. Small piece of hobby sheet metal 0.008" thick.

I started curling it by hand then wrapped it around a wooden dowel that was approximately the same size as the piston ID.

Then cut some notches into one end--this will be the front.

It's a tall crown! Looks like

Jughead's hat.

Now fold the notches inward at a 90 degree angle.

I slid the dowel rod inside and stood it up on the workbench--notches down. A smack with a dead-blow hammer formed it right up.

Looks promising.

A bit of trial and error fitting is always required. It's right when the shim fits into the piston body tightly, doesn't block the cocking lever slot, and the spring fits inside snugly. The front end of the spring bears on the folded notches--that keeps the guide inside the piston.

Removed the bolt on the rear of the loading assembly.

The loading bolt slides right out. I polished the entire bolt on the buffer and got out the

moly.

Where to get

molybdneum disulphide grease in most locales? Honda motorcycle dealers. Honda specifies it's use on the splines of the shaft drives. It's 60%

moly. A few years supply will set you back about $10. Cheap thrills.

The bolt and spring got a thin coat. This part is now lubed for the next decade or more.

Unscrewed the barrel. Warning-- the receiver is plastic--I mean "polymer". With the barrel removed, it got cleaned with

JB Non-Embedding bore cleaner.

Time to remedy the factory spring guide. Cut off a 2.75" piece of 0.875" drill rod.

Faced the ends and turned it down to 0.564" to fit inside the mainspring.

Made it 2.563" long--again, not counting the flange.

Unscrewed the knurled nut,

...and pushed out the pin the cocking lever latches onto. It's not on the schematic.

A dowel inserted into the compression tube can be driven forward...

To press out the front steel cap. (The front cap also isn't on the schematic that came with my rifle. ) It's solid steel with an o-ring to air seal the front of the tube. The o-ring is a size P20. It's 2.4mm thick and 19.8mm OD.

There's a small notch on the inside top of the cap. The notch is on top and directs the air as part of the transfer port.

Smoooooth

Smoooooth for the piston seal. Horribly scarred for the spring. At least Baikal got it right where it counts.

Another better(?) view.

The catch bar is the key piece in the anti-

beartrap ratchet system. It slides fore and aft in the shallow notch in the end cap--the "cocking lever base" in the manual.

Kinds fuzzy, but you get the idea. The angled end of the catch bar faces rearward and sits just UNDER the ratchet assembly of the cocking lever catch.

Side view. With the end cap out of the gun, it's possible to install the cocking lever and pivot pin as a test fit. You can then put the catch bar into place and see how it unlocks the ratchet assembly from the cocking lever when pushed rearward. What moves the catch bar rearward when it's in the gun? When cocked, the piston is pulled back by the cocking lever. At the very end of it's rearward travel, the back edge of the piston body pushes the catch bar backwards.

Moly

Moly on the spring. Very thin coat.

Moly

Moly on the piston body and sides of the piston seal.

I replaced the o-ring on the front cap and reinstalled it. Installed the piston/spring/spring guide into the compression tube from the rear.

Used some

moly to hold the catch bar in place, braced the end cap against the side of the work bench and leaned into it.

Need to line up the tab on the end cap with the slot.

Then the tab is rotated into a notch to lock the end cap in place.

Rocker is dropped into the front hole of the cocking lever slot and into the piston body. Rear (pivot) end of the cocking lever is reinstalled and aligned with pivot pin hole using a small drift. Pivot pin installed. At this point the cocking lever is probably NOT lying flush against the compression tube. It's very likely being held by the anti

beartrap mechanism. For simplicity sake, complete the assembly with it like that.

Reassembled the trigger and both sears. A bit of

moly on all the sliding contact surfaces.

Installed the stock screws. The forward stock screw was giving me fits falling off the screwdriver as I tried to install it inside the forearm. A few passes through the

Wiha magnetizer/demagnetizer and the screw won't fall off the tool.

Stock reinstalled.

Assembly done.

Now the bad part: I fired a hundred or so shots to distribute the lubricant inside the gun. I thought the gun fired just...OK. There was no vibration or noise from the mechanism but I noticed some rather pronounced spring torque. It was noted mainly because it wasn't present at all before the tune and the gun is so light it's simply more perceptible. A nine pound gun would probably have masked all the spring torque. Then I fired the gun over the chronograph and the numbers were down around 435 fps with Hobby pellets. Ouch. I knew there would be some velocity loss, but this is clearly too much. What went wrong? Pretty clearly, I erred on the side of tightening up the spring fit tolerances too much. The 61 just doesn't have the spring power to overcome the frictional losses from the tightly fitted spring guide, sleeved piston, and the moly grease. I pulled the gun completely apart and started over. I removed the piston sleeve and relubed the gun with a razor thin coat of

Buzzy's Slick Honey grease. Another hundred break-in shots and back to the chronograph. The spring torque was still there, though the velocity had climbed to 448 fps. Better, but the spring torque had to go. The amount of spring compression meant there really wasn't any room for rotation washers. Besides, the base of the spring guide was already able to pivot against the smooth plastic, sorry POLYMER, of the end cap. I pulled the end cap a third time and just removed the spring guide. Chucked it back into the Taig lathe and reduced it to a looser fitting 0.552" diameter. A touch of Buzzy's and it went back together. The spring torque was gone and the velocity climbed again to the 460 fps mark. I'll leave it here and check it again after about 2000 additional shots. I think the velocity will slowly edge up to about 480--485 fps and stabilize as the piston seal moves any excess grease out of it's way. Smooth shot cycle and velocity consistency are far more important factors that outright power in a low-powered target gun like this. The gun need only shoot fast enough to punch clean, easy to score holes in the target. Crap. I'm rationalizing.

Notes: Lubing the piston seal with Buzzy's grease wouldn't be my first choice for a gun prone to diesel, but the low power of the 61 ensures that's not gonna happen.