I decided to start selling Morgan Adjustable Recoil Pads to generate a little income to subsidize all my airgun purchases and blogging. I set up a web page where I sell the pads . The main reason for installing one of these recoil pads on an air rifle is not to tame the recoil of the airgun but to drop the butt of the rifle, and lengthen the pull for a more comfortable fit.

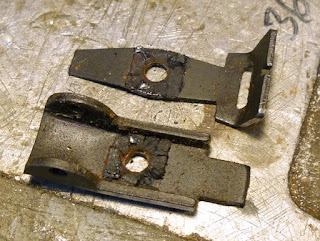

The stock butt plate on the Baikal 513M.

Removed. If this were a firearm I'd probably fill the counterbored holes, as it was I just plugged the actual screw holes with dowels.

Now to mount it.

I marked the centerline of the butt.

Although the hole spacing is identical, I need to offset the recoil pad so that it is centered on the buttstock..

To do this I flipped the bottom plate over to ensure that the adjusting mechanism was entirely on the butt.

I marked the new screw locations with pencil.

I drilled for one screw hole.

Notice the original hole is plugged.

I temporarily screwed the pad on and took care to align the second screw hole on the centerline.

I used a transfer punch to mark the 2nd hole. I wrapped some masking tape around the end of the butt to protect the finish.

Drilled and screwed on.

I then flipped the stock over and scribed the contour of the butt on the plastic.

Now I have a guideline for trimming.

I used my favorite file for plastic, a Nicholson Magicut file

Almost there.

I then sanded carefully with a sanding block.

Looks good.

I sanded it smoother with some 400 grit paper. In hindsight I should have gone to 600 and maybe even 1200 to get a better finish. I did rub it with plastic polish which shined it up a bit in the later pictures.

The bottom half of the pad mounted with the adjusting screw in place.

Overall I'd say it took me about an hour of patient work. I have yet to do one of the aluminum recoil pads but that would require a belt or disc sander, or a lot of physical work to trim to size.

The drop I need to be comfortable with this air rifle.

The Baikal 513M in the rifle in the center. Notice an old style aluminum pad on the Diana 45 air rifle above it.