Finally found some time to put the A.B.T. back together…

This needed some fixing.

My precision drawing.

Surgery.

An attempt at precision.

A walnut block.

JB Weld. Why? Because I was out of clear epoxy and didn’t have time to go to the hardware store. It’s not going to be visible.

Clamped up. I let it cure for a day.

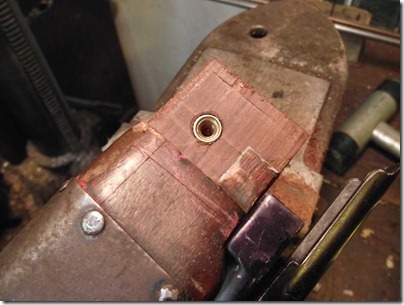

I roughed out the block with the mill.

Almost done.

I left it oversize so I could fit it after I reassembled the rifle.

Another shot of the receiver.

Sear.

Fitting…there was a bunch of chiseling and rasping.

Now to drill the hole for the bushing. I left those steel plates because they look cool. This was a gun that was used by thousands of people.

Fitted.

The wood broke out as I was drilling – from this side…some days I can’t win. But again, nobody will see it. Except you guys.

Some air fittings.

A long drill bit, paper and glue.

Makes a tube.

I decided to try regular .170” BBs first.

In the loading trough.

Plink.

Airgun dork.

This is at 15’

I then tried .177 lead balls. I loaded them directly in the trough without a tube. Which worked fine, FYI.

And 3/16” ball bearings, which are I believe the ammunition the rifle is supposed to use. These were all at 80psi from my crappy compressor – I wonder if more pressure was warranted. I’ll bring it over a friend’s shop sometime and see how it does with more air pressure.

Making a tube for 3/16 ball bearings.

Exciting as watching glue dry.

Glue drying…So that's pretty much it. A nice piece of Carnival history. Now I just need to find a complete shooting gallery and I can have a nice summer job.

0 comments:

Post a Comment