I really didn’t know what I was dealing with…

Levering out the brass ring (I used a small screwdriver in the slots) so I could get a better look in the cavity for the seal. Notice the pot metal fracturing. I had to use gravers to remove the excess metal trapping the ring. In hindsight I suppose I could have left the ring in place.

Although with the ring removed I was able to measure for the diameter of the seal. The ring got beat up in the process. I wonder if Gamo just swaps the whole valve assembly when they service the pistols?

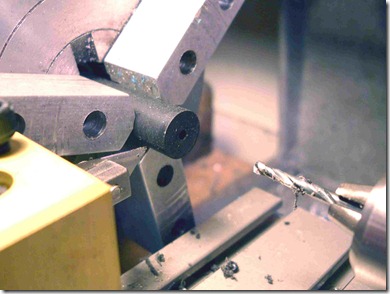

Drilling the seal hole.

Turning down to diameter.

Cutoff. The first one I made was about .05” thick, later I made another than was about .04” which worked better. The seal is basically just a flat disk.

Seal in place.

Brass ring pushed in. In theory it should stay put.

Testing the assembly with a used (empty) cartridge. Reassembly of the pistol was in the reverse order of disassembly. I managed to flip the “teflon” exhaust seal around and at first the pistol wouldn’t function, I disassembled the pistol several times and finally realized that I had it flipped. It now functions normally and holds gas. Once I get some clips I’ll test it out and see if there are any other problems.

0 comments:

Post a Comment