I bought this Thompson/Center rear sight unit on a whim at the Gun Shoppe about a year ago and threw it in the parts box.

I thought the curved base looked about right for a 22XX gas tube. And it is.

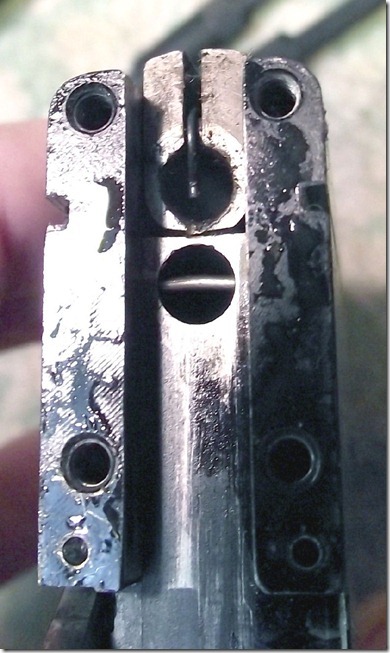

The only problem with the T/C sight is the leaf is much too narrow to acquire the correct sight picture on a 10-meter pistol target. The piece on the bottom is a spare leaf from an IZH-46M.

My initial thought was to simply attach the IZH leaf directly to the T/C unit.

Except the T/C is too narrow.

I could move the bolt holes, but where's the fun in that?

Removed the windage screw...

and the sight blade and spring came out.

Still too narrow. I like the idea of being able to interchange leafs of differing widths--and I'd prefer to have some uniformity, if there is such a thing. So it might prove useful to make the T/C sight accept IZH leafs. An adapter of some sort is required.

Went through the box of metal and found a piece of what's probably cold rolled steel. A small machinist square (they let anybody buy these things) confirmed that the sides were 90 degree angles. This is good--it means less work for me.

A bit of layout fluid and some quick measuring was next.

Almost all the numbers are arbitrary. I elected to make the "adapter" wider than the stock T/C blade then drill and tap mounting holes so the IZH leaf will attach.

Cut out a rectangle from the raw material then milled to length. (front to back measurement)

And squared up the width. I used 32mm as the arbitrary number. The piece just needs to be wide enough for the bolt hole spacing in the IZH leaf.

Milled out the clearance on the sides.

A "T" shape.

Reduced the height of the center boss on the top. It would work fine as it is, but it better fits the lines of the sight base...

Not shown: Milled, then sanded, the rear of the adapter at an angle. Want the leaf angled backward slightly to reduce glare.

Getting there. More to come in a couple days.